How Is Candy Corn Made? A Journey into the Sweet Science

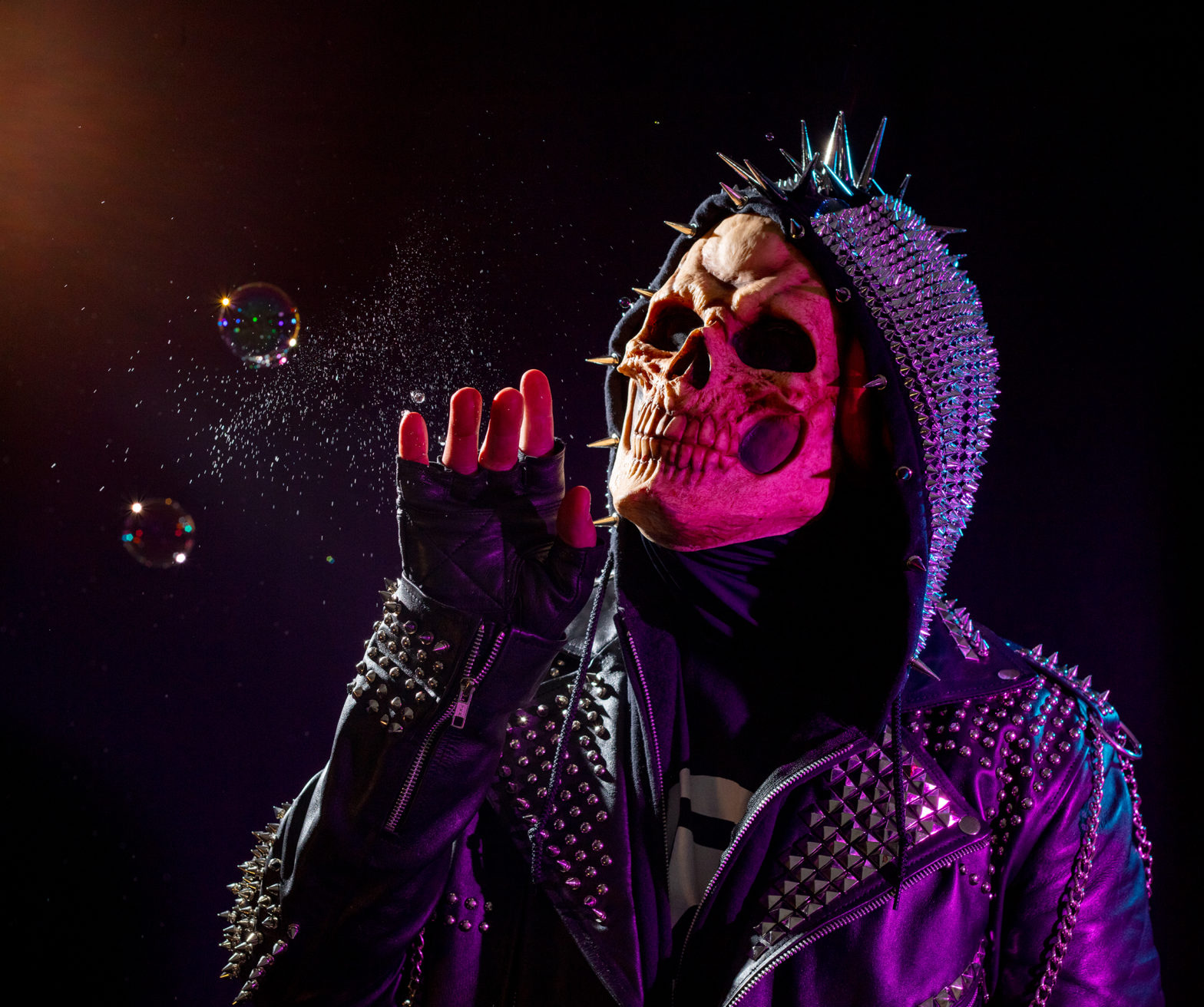

As Skeleton Sam, there’s nothing I love more than a handful of candy corn—except maybe knowing exactly how my favorite treat is made. This iconic Halloween candy, with its tri-colored layers and sweet flavor, has a fascinating production process that combines science, precision, and a bit of magic. Let’s dive into the delicious details of how candy corn is made!

The Ingredients

Candy corn is crafted from a blend of simple ingredients:

- Sugar: The primary component, providing the sweet base.

- Corn Syrup: Adds the chewy texture and enhances the sweetness.

- Confectioner’s Glaze: Gives candy corn its shiny, irresistible finish.

- Salt: Balances the sweetness and enhances the flavor.

- Dextrose: Another form of sugar that helps with the candy’s texture.

- Gelatin: Adds a slight firmness to the candy.

- Honey: Contributes to the flavor and chewiness.

- Artificial Flavors and Colors: Provide the classic candy corn taste and the iconic orange, yellow, and white colors.

The Mixing Process

The journey of candy corn begins with mixing these ingredients into a syrup. Sugar, corn syrup, honey, and other ingredients are heated in large kettles, creating a thick, gooey mixture. This syrup is cooked until it reaches the perfect consistency, ensuring the candy will have the right texture and flavor.

Molding and Layering

The signature look of candy corn comes from its layered appearance. This is achieved through a process called “corn starch molding.” Here’s how it works:

- Trays of Corn Starch: Trays are filled with cornstarch, which is then imprinted with candy corn-shaped molds.

- Layering the Syrup: The hot syrup is poured into the molds in three stages to create the iconic tri-colored layers. The first layer is white, followed by orange, and finally yellow. Each layer is allowed to set slightly before the next one is added.

Cooling and Setting

Once the candy corn pieces are fully formed in the molds, they need time to cool and set. This step is crucial for ensuring the candies maintain their shape and texture. The trays are placed in a controlled environment where they can cool gradually.

Glazing and Polishing

After cooling, the candy corn pieces are removed from the molds and go through a glazing process. This involves tumbling the candies with confectioner’s glaze to give them a shiny finish. This step not only makes the candy corn look more appealing but also helps preserve its freshness.

Packaging

Finally, the finished candy corn is sorted and packaged for distribution. Quality control measures are in place to ensure that each piece meets the standards of appearance and taste that candy corn lovers expect. The candies are then packed into bags, ready to be shipped to stores and eventually into the hands of eager Halloween enthusiasts.

The Sweet Result

And there you have it—the sweet science behind the creation of candy corn! From mixing the ingredients to molding the layers and glazing the final product, each step is a carefully orchestrated process that results in the beloved treat we all enjoy. Next time you munch on a handful of candy corn, you’ll have a newfound appreciation for the craftsmanship and care that goes into every piece. Happy Halloween, and enjoy your candy corn!

Leave a Reply